Flat lens offers a perfect image

By Jakob Schiller

Camera lenses might look radically different in a couple years thanks to a new technology developed by a group of physicists at the Harvard School of Engineering and Applied Sciences (SEAS).

Using a very thin wafer of silicon the scientists have created a flat lens that is only 60 nanometers thick and does away with the normal curved glass we’re used to seeing on most cameras.

“Our website almost went down because of all the hits,” says Federico Capasso, the principal investigator on the project and a Robert L. Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering at SEAS. “People are seeing the revolutionary potential.”

Curved glass is currently used to make camera lenses because it can bend the light coming from many angles in such a way that it all ends up at the same focal point, be that a slice of 35mm film or an electric sensor.

The problem with curved glass is that it produces aberrations, or distortions. Capasso says that oftentimes the light captured at the very edges of a curved glass lens does not line up correctly with the rest of the light, creating a fuzzy focus at the edge of the frame.

To correct this, these lenses use extra pieces of glass, adding weight and mass.

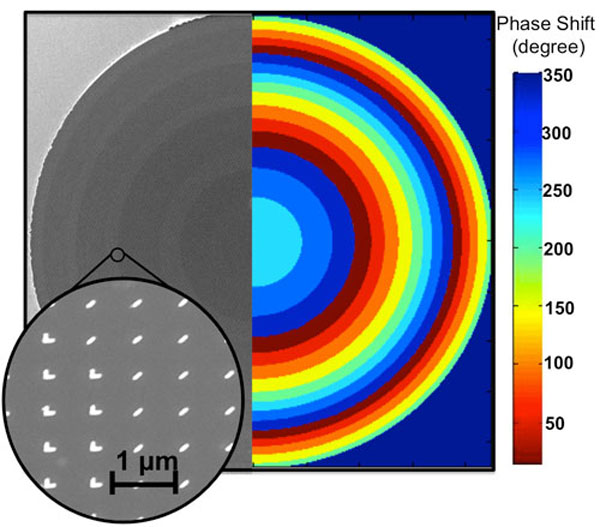

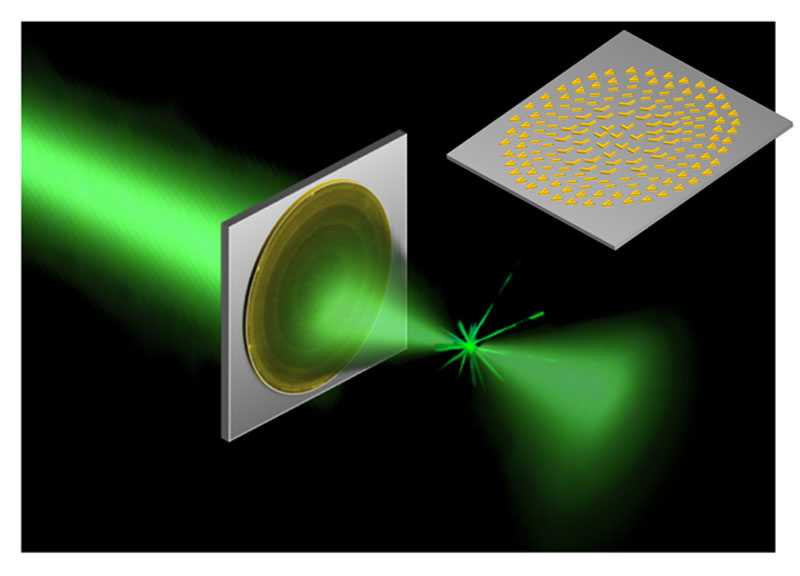

On the flat lens created by Capasso and his colleagues, a series of small nano structures, what they call nanoantennas, are systematically arranged on the silicon wafer and when the light hits these antennas they do the job of refracting the light so that it all ends up on the same focal plane.

“What we’ve done is create an artificial refraction process,” Capasso says.

The angle at which the light is refracted — more at the edges than in the middle, just like a curved glass lens — depends on the shape, size, and orientation of the antennas, he says.

The antennas on the current lens can only focus one wavelength of light. But Capasso says the team plans to eventually build broadband antennas that can handle normal white light, which is polychromatic, or made up of multiple wavelengths.

We’re guessing that normal lenses won’t leave the market anytime soon, but the possibility of a new, mass-produced lens that eliminates aberrations and bulk is certainly something to look forward to.

“It’s extremely exciting,” Capasso says.

Applied physicists at the Harvard School of Engineering and Applied Sciences (SEAS) have created an ultrathin, flat lens that focuses light without imparting the distortions of conventional lenses.

At a mere 60 nanometers thick, the flat lens is essentially two-dimensional, yet its focusing power approaches the ultimate physical limit set by the laws of diffraction.

The results have been published online in the journal Nano Letters.

“Our flat lens opens up a new type of technology,” says principal investigator Federico Capasso, Robert L. Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering at SEAS. “We’re presenting a new way of making lenses.

Capasso and his collaborators at SEAS create the flat lens by plating a very thin wafer of silicon with a nanometer-thin layer of gold. Next, they strip away parts of the gold layer to leave behind an array of V-shaped structures, evenly spaced in rows across the surface. When Capasso’s group shines a laser onto the flat lens, these structures act as nanoantennas that capture the incoming light and hold onto it briefly before releasing it again. Those delays, which are precisely tuned across the surface of the lens, change the direction of the light in the same way that a thick glass lens would, with an important distinction.

The flat lens eliminates optical aberrations such as the “fish-eye” effect that results from conventional wide-angle lenses. Astigmatism and coma aberrations also do not occur with the flat lens, so the resulting image or signal is completely accurate and does not require any complex corrective techniques.

“In the future we can potentially replace all the bulk components in the majority of optical systems with just flat surfaces,” says lead author Francesco Aieta, a visiting graduate student from the Università Politecnica delle Marche in Italy. “It certainly captures the imagination.”